What is Pulse Laser Cleaning & How Does It Work?

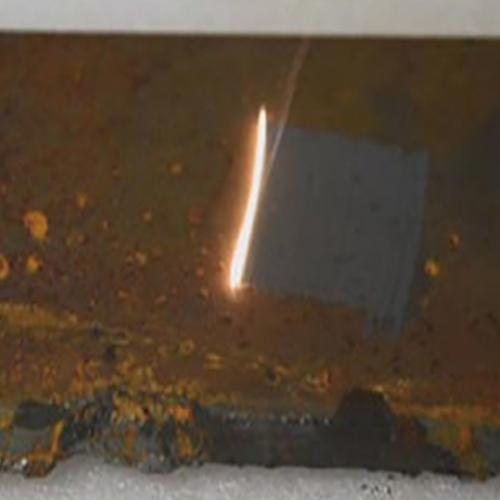

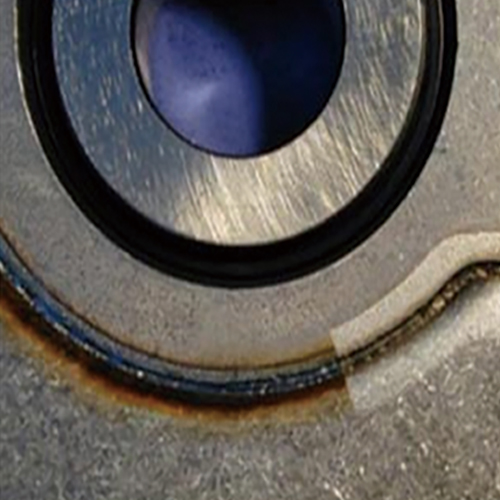

Pulse laser cleaning machines utilize short, intense bursts of laser energy to remove contaminants from surfaces without damaging the underlying material. The laser pulses generate a rapid expansion of plasma on the surface, which lifts off rust, paint, dirt, or other unwanted layers. This technology is highly controlled, allowing for precision cleaning of even delicate surfaces.

What Materials Can It Clean?

Pulse laser cleaning is especially effective on materials that require precise cleaning without thermal damage. This includes metals like steel, aluminum, and copper, as well as delicate surfaces like certain plastics and composites. The controlled nature of the laser pulses ensures that only the unwanted layers are removed, preserving the integrity of the base material.

Industries and Specific Applications

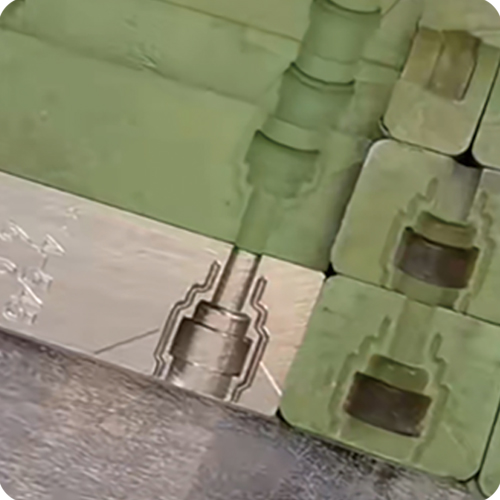

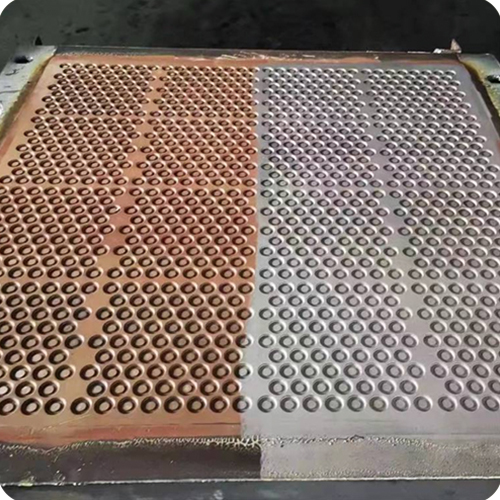

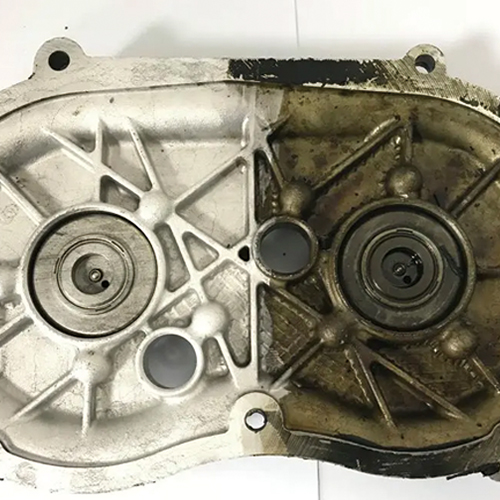

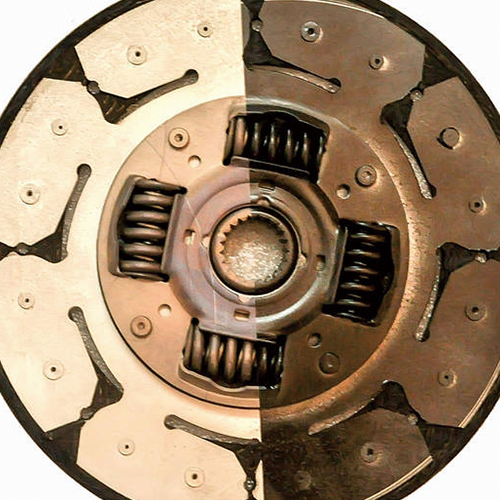

Pulse laser cleaning machines are widely used in industries such as aerospace, automotive, and electronics. Specific applications include removing rust and oxidation from metal parts, cleaning molds in manufacturing, and preparing surfaces for bonding or coating. In the electronics industry, pulse lasers are used to clean delicate components without causing thermal damage.

Metal rust and other dirt cleaning, before and after

1885 S Vineyard Ave ، أونتاريو ، 91761

214101 رقم 188 ، طريق يويي الأوسط ، مدينة ووشى

هل لديك أسئلة أو تحتاج إلى مساعدة؟